|

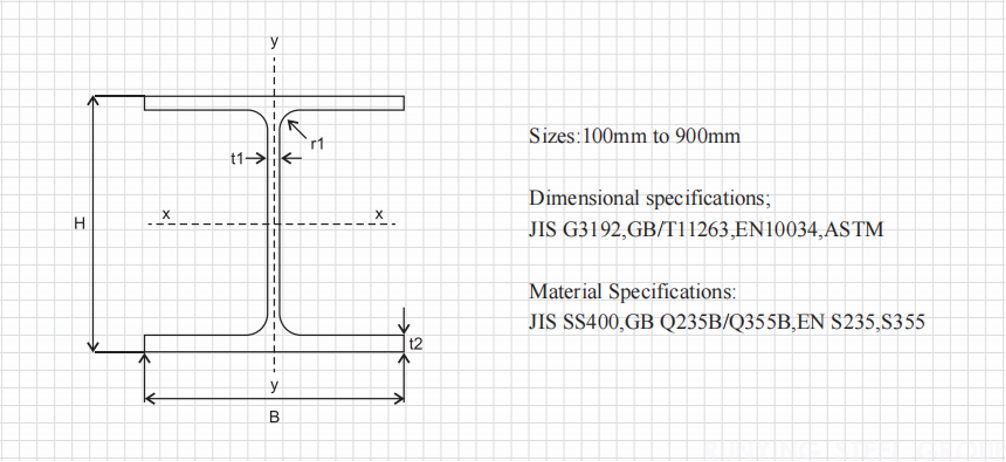

H Steel Beam

Metal H Steel Beam, rolled on universal mills with optimized flange-web thickness. Compliant with GB/T 11263, ASTM A6, EN 10025 for skyscrapers, bridges, and heavy industrial structures. |

Product Name: Hot Rolled Metal H Structural Section Beam

Overview:

Rolled on universal mills with optimized flange-web thickness. Compliant with GB/T 11263, ASTM A6, EN 10025 for skyscrapers, bridges, and heavy industrial structures.

Technical Specifications:

| Size(mm) | Kg/m(GB) | Kg/m(JIS) | Size(mm) | Kg/m(GB) | Kg/m(JIS) |

| 100*100*6*8 | 17.2 | 16.9 | 388*402*15*15 | 141 | 140 |

| 125*125*6.5*9 | 23.8 | 23.6 | 390*300*10*16 | 107 | 105 |

| 148*100*6*9 | 21.4 | 20.7 | 394*398*11*18 | 147 | 147 |

| 150*75*5*7 | 14.3 | 14 | 394*450*18*18 | 169 | 168 |

| 150*150*7*10 | 31.9 | 31.1 | 396*199*7*11 | 56.7 | 56.1 |

| 175*90*5*8 | 18.2 | 18 | 400*200*8*13 | 66 | 65.4 |

| 175*175*7.5*11 | 40.3 | 40.4 | 400*150*8*13 | 55.8 | 55.2 |

| 194*150*6*9 | 31.2 | 29.9 | 400*400*13*21 | 172 | 172 |

| 198*99*4.5*7 | 18.5 | 17.9 | 400*408*21*21 | 197 | 197 |

| 200*100*5.5*8 | 21.7 | 20.9 | 414*405*18*28 | 233 | 232 |

| 200*200*8*12 | 50.5 | 49.9 | 414*202*10*20 | 94.5 | 93.9 |

| 200*204*12*12 | 56.7 | 56.2 | 428*407*20*35 | 284 | 283 |

| 244*175*7*11 | 44.1 | 43.6 | 440*300*11*18 | 124 | 121 |

| 244*252*11*11 | 64.4 | 63.8 | 446*199*8*12 | 66.7 | 65.1 |

| 248*124*5*8 | 25.8 | 25.1 | 450*200*9*14 | 76.5 | 74.9 |

| 250*125*6*9 | 29.7 | 29 | 458*417*30*50 | 415 | 415 |

| 250*250*9*14 | 72.4 | 71.8 | 482*300*11*15 | 115 | 111 |

| 250*255*14*14 | 82.2 | 81.6 | 488*300*11*18 | 129 | 125 |

| 294*200*8*12 | 57.3 | 55.8 | 496*199*9*14 | 79.5 | 77.9 |

| 294*302*12*12 | 85 | 83.5 | 498*432*45*70 | 605 | 604 |

| 298*149*5.5*8 | 32.6 | 32 | 500*200*10*16 | 89.6 | 88.1 |

| 298*201*9*14 | 65.9 | 64.4 | 506*201*11*19 | 103 | 102 |

| 300*150*6.5*9 | 37.3 | 36.7 | 582*300*12*17 | 137 | 133 |

| 300*300*10*15 | 94.5 | 93 | 588*300*12*20 | 151 | 147 |

| 300*305*15*15 | 106 | 105 | 594*302*14*23 | 175 | 170 |

| 338*351*13*13 | 106 | 105 | 596*199*10*15 | 95.1 | 92.4 |

| 340*250*9*14 | 79.7 | 78.1 | 600*200*11*17 | 106 | 103 |

| 344*348*10*16 | 115 | 113 | 606*201*12*20 | 120 | 118 |

| 344*358*16*16 | 131 | 129 | 692*300*13*20 | 166 | 163 |

| 346*174*6*9 | 41.8 | 41.2 | 700*300*13*24 | 185 | 182 |

| 350*175*7*11 | 50 | 49.4 | 192*300*14*22 | 191 | 188 |

| 350*350*12*19 | 137 | 135 | 800*300*14*26 | 210 | 207 |

| 350*357*19*19 | 156 | 154 | 900*300*16*28 | 243 | 240 |

Key Advantages:

1. Structural Efficiency

H Beam: 35% higher bending resistance

I Beam: 15% material savings in connections

2. Global Standards

China: GB/T 11263

USA: ASTM A6

EU: EN 10025

3. Heavy-Duty Performance

Q355B H Beam: Yield ≥355MPa, spans up to 45m

A992 I Beam: Fy/Fu≤0.85 (seismic requirement)

4. Connection Precision

Milled flange ends (±0.5mm)

Pre-punched web holes (±1mm)

5. Lifecycle Economy

22% cost saving vs welded beams

100% recyclable (EPD certified)

Get Your H Beam Quote Now!

Runying Steel Group Company occasionally has low/mild/high carbon discount steel products for sale at a low price. For more information, please follow our public Facebook page (https://www.facebook.com/tangsteel) or contact our sales team directly.