|

Galvanized Steel Coil / GI Coil

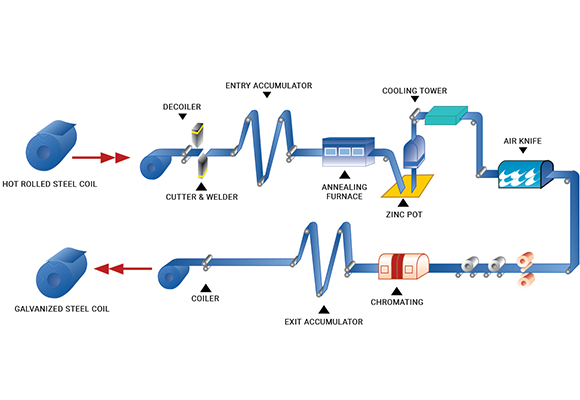

Hot-Dip Galvanized Steel Coil (GI/GL) Through continuous hot-dip galvanizing process, we produce corrosion-resistant steel coils with zinc-iron alloy layers. Combining high strength with 20+ years service life, ideal for harsh-environment applications. |

Product Name: Hot Dip Galvanized Steel Coil (GI/GL)

Overview

Through a continuous hot-dip galvanizing process, we produce corrosion-resistant steel coils with zinc-iron alloy layers. Combining high strength with 20+ years service life, ideal for harsh-environment applications.

| Name | Galvanized Sheet Metal in Coil |

|---|---|

| Base Material | SGCC/ SGCH/ DX51D/ DX52D/ DX53D/ DC01/ DC03/ DC04 |

| Zinc Coating | Z30-600g/m² |

| Thickness | 0.09-6.0mm |

| Width | Coil:600-1500mm / Strip: 20-600mm |

| Surface Treatment | Regular Spangle/Zero Spangle/Passivation/Oiled |

| Corrosion Class | C2-C5 (ISO 12944) |

| Standards | EN 10346, JIS G3302, ASTM A653 |

Superior Corrosion Resistance

Salt spray resistance ≥1000hrs (ASTM B117) at 100g/m² zinc coating

Excellent Formability

Withstands 180° bending without zinc peeling, suitable for stamping/roll-forming

Eco-Efficiency

3x longer lifespan than paint coatings, reducing lifecycle cost

Versatile Surface Options

Chromate passivation/anti-fingerprint treatments for enhanced paint/weldability

Construction: Steel structures, roofing sheets, HVAC ducts

Transportation: Highway guardrails, noise barriers, bridge cladding

Agricultural: Grain silos, harvester components

Appliances: Washing machine drums, outdoor AC frames

Solar Energy: PV mounting systems, electrical enclosures

Runying Steel Group Company occasionally has low/mild/high carbon discount steel products for sale at a low price. For details, please follow our public Facebook page (https://www.facebook.com/tangsteel ) or contact our sales team.

Get Your Iron Metal Steel Coil Quote Now!